Aquacera Iron and Sulfur Removal For Well Water Air Injection Whole House Water Filters.

|

|

|

|

Aquacera Iron and Sulfur Removal For Well Water Air Injection Whole House Water Filters.

|

|

SKU:

Weight:

50

lbs

0

ozs

Aquacera Iron and Sulfur Removal For Well Water Air Injection Whole House Water Filters. System Benefits: No chemicals, safe for septic beds, inexpensive operation, simple design, only uses air to precipitate iron and hydrogen sulfide (rotten egg smell). Exclusive off air tank system eliminates water pipe hammering and sputter in faucets. Allows air contact time with water for better results. These systems will not work with variable speed well pump. More details... |

|

Please Select Model:

|

|

|

|

|

|

| |

|

Product Details

|

Iron and Sulfur Removal For Well Water. Air Injection Whole House Water Filters. No chemicals, safe for septic beds, inexpensive operation, simple design, only uses air to precipitate iron and hydrogen sulfide (rotten egg smell). Exclusive off air tank system eliminates water pipe hammering and sputter in faucets. Allows air contact time with water for better results. These systems will not work with variable speed well pump.

Model: ACBTC-AB10 Designed for homes with 1-3 bathrooms, Birm media

Designed for homes with 1-3 bathrooms, Birm™ media. Dimensions: H -55 3/4" D - 14 ¾" w/bypass or 10 ½" w/o bypass, Off Air Tank H -43" W -8"

Uses free air to precipitate the iron and sulfide (sulfur) in your well water. | - Fully automatic

- Up to 15 ppm of clear iron

- Iron removal red 8 ppm

- 10" x 47" tank

- Bypass valve

- Clack 1" air injection valve standard.

- 10 year warranty (limited)

| - Self cleaning backwash

- Up to 2 p.p.m. manganese

- Off air system 8" x 35" tank

- Service flow 7 g.p.m.

- Off air tank

- Sulfides (sulfur) to 4 p.p.m.

- Working pH: 6.8-9

|

Model: ACBTC-AB12 Designed for homes with 3-6 bathrooms, Birm™ media

Designed for homes with 3-6 bathrooms, Birm™ media. Dimensions: H -62 3/4" D - 14 ¾" w/bypass or 12½" w/o bypass, Off Air Tank H -43" W -10"

|

- Fully automatic

- Up to 15 ppm of clear iron, red iron 8 ppm

- Iron removal red 8 ppm

- 12" X 52" tank

- Bypass valve

- Clack 1" air injection valve standard.

- 10 year warranty (limited)

| - Self cleaning backwash

- Up to 2 p.p.m. manganese

- Off air system 10 " x 43" tank

- Service flow 7 g.p.m.

- Off air tank

- Sulfides (sulfur) to 6 p.p.m.

- Working pH: 6.8-9

|

Model: ACBTC-AC12 Designed for homes with 3-6 bathrooms, Catalox™ media

Designed for homes with 3-6 bathrooms, Catalox™ media. Dimensions: H -62 3/4" D - 14 ¾" w/bypass or 12½" w/o bypass, Off Air Tank H -43" W -10"

|

- Fully automatic

- Up to 15 ppm of clear iron, red iron 8 ppm

- Iron removal red 8 ppm

- 12" X 52" tank

- Bypass valve

- Clack 1" air injection valve standard.

- 10 year warranty (limited)

| - Self cleaning backwash

- Up to 2 p.p.m. manganese

- Off air system 10 " x 43" tank

- Service flow 7 g.p.m.

- Off air tank

- Sulfides (sulfur) to 2 p.p.m.

- Working pH: 6.5-9

| Model: ACBTC-AB12M Same as above iron and sulfur removal filter system with Mazzei injector for up to 20 g.p.m. flow rate.

Model: ACBTC-AB14M Commercial iron and sulfur removal filter system with Mazzei injector and by-pass valve, 14"x52" filter tank w/flow rate up to 20 g.p.m.

Larger systems available for 1.25", 1.5" and 2" timed valves as well Mazzei Injector with bypass assembly for high flow rate applications.

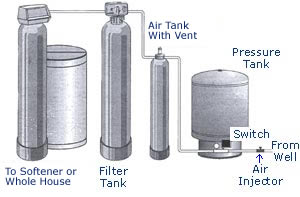

Aquacera Iron and Sulfur Filter Systems consist of an air injector, mixing tank and filter tank. The other basic equipment that should be installed or exist as part of the water system and the filter components are highlighted below.   Air Injector - The operation of the nozzle/venturi air injector - As you can see by the diagram on far left, as water enters the air injector it is split between the nozzle portion of the injector and the bypass portion. The amount of water entering the nozzle area is regulated by the bypass screw. The further the screw is tightened (clockwise) into the air injector the greater the flow of water into the nozzle. Air Injector - The operation of the nozzle/venturi air injector - As you can see by the diagram on far left, as water enters the air injector it is split between the nozzle portion of the injector and the bypass portion. The amount of water entering the nozzle area is regulated by the bypass screw. The further the screw is tightened (clockwise) into the air injector the greater the flow of water into the nozzle.

To achieve proper air injection with good water flow the simple rule of thumb is to turn the bypass screw all the way in until stop then back it off one full turn (counter clockwise 360°).

As the water is restricted into the nozzle and enters the venturi a vacuum is formed at this point. This vacuum creates the air draw into the water. This is the standard air injector included with our Iron and Sulfur Systems. This plastic air injector features plumbing connections of 1 female pipe threads (FTP) and a flow range for effective air draw of 3.8 16 GPM.

Pressure Switch A good quality pressure switch should be installed after the air injector and before the Pressure Tank. The switch should be set to turn the well pump on at a minimum of 30 psi and off at 50 psi. Please keep in mind that the pressure switch must be installed AFTER the air injector as illustrated.

Pressure Tank - A good quality pressure tank should be installed to insure sufficient run time on the well pump.

The Mixing Tank As oxygenated water enters the mixing tank it is sprayed through a series of holes enhancing the oxidation process and venting excess oxygen from the water supply. Water is picked-up off of the bottom of the tank by an outlet tube as it exits the tank. The excess air is picked-up by a small tube and vents to an air release located on the top of the mixing tank. The air release features both an on and off position which allows for disassembly without turning off the entire system. The air release should be in the OPEN position when operation allowing excess air to vent to drain. The air release fitting and tubing should be attached to the air release and run to an open drain. The tubing will direct any water discharged by the air release to the drain. Make sure you adhere to local plumbing codes when installing this tubing at the drain.

The Filter Tank - As the oxygenated water enters the filter tank the precipitated iron is filtered by the media in the tank and any dissolved iron left in the water is removed by the media. The Filter tank should be back-washed approximately every three days to clean the bed and redistribute the filter media.

This is printable and simplified installation diagram and instruction. Each system comes with full instruction however it can be complicated as the microprocessor is designed for all other sorts of filters.

WHOLE HOUSE FILTERS: AquaCera™ solid state control microprocessor |  | Features - Solid state microprocessor with easy access front panel settings

- Double backwash feature offers efficiency and optimum regeneration and cleaning ability

- Days between regeneration feature: 7/99 days standard

- Down flow regeneration

- Stores system configuration and operation data in nonvolatile memory

- 12-volt transformer provides safe and easy installation

- Control valve design provides optimum service and backwash rates

Bypass valve included |

|

|

|

|